A couple of years back I wrote an article about Spring Mill/Daisy Spring Distillery that I felt like needed some updating as in the time in between then and now I’ve learned quite a bit more about the history of the old Daisy Spring Mill and Distillery. I recently was allowed to copy some documents in possession of the distillery/mill/park which shined a brilliant light on the distilling happening there at least in the 1880’s. I also discovered the name of the original distiller employed on the site by Hugh Hammer in the 1830’s.

In the original article I also speculated a bit about the amount of whiskey made at the time based on an older document, as it turns out the information about the capacity of that distillery in the older document was actually related to the nearby (Mitchell Indiana) and much larger Irwin distillery which I am currently researching and which did produce up to 135 gallons of whiskey a day and had a capacity of around 38 bushels a day roughly.

As a quick recap I’ll now give a bit of a history of the distillery itself:

Sam Jackson acquired the land as payment for his service in the war of 1812 and later sold the property to the Bullitt family in 1819. I am a bit confused on the history of the original mill as it was a small affair built of logs and made of one room, the initiator of that business could have been either Jackson or the Bullitt’s but it is clear that in these earliest days there was a small distillery run in conjunction with the mill on the property. In short order the mill could not keep up with demand and was sold then to the Montgomery brothers in 1823.

The Montgomery brothers lived in Pittsburg and were apparently very speculative regarding their investment as the western frontier in Indiana was just beginning to grow, apparently, they both bought and sold the property sight unseen and spent a small fortune building and renovating the large three-story stone mill you see today. It was at this time that they hired John Hammersley of Clifty Mill (Cave River Valley Fame) to be their millwright and oversee the implementation of new gristing equipment using his knowledge as well as that found in the book; “The Young Miller and Millwright”. At the time Hammersley was seeing much success with his own milling operations in Washington County both in the form of profit from milling and subsequent distilling but also in his ability to build unique milling operations and sell them at a profit to speculators in the nearby community. I am sure Hammersley sensed a valuable payday in his work for his bosses in absentum as he left a young Hugh Hammer and his brother Thomas back at Clifty Mill to run his own enterprises until the Montgomery mill was updated and ready to run somewhere around the year 1825.

That year Hammersley returned to Clifty and informed Hugh Hammer that he was moving elsewhere in Indiana to pursue a new mill and would be selling his interest to his son but that the Montgomery brothers would be in need of a miller at their new location. Without much further thought Hammer and his brother Thomas loaded up and headed for the springs outside of Mitchell Indiana. In short order, they ended up owning the mill despite their impoverished position in life as the Montgomery brothers passed away thereafter and what seems to be a “well timed” rumor about a large crack in the wall of the mill made its way back to one of their sons who was now in charge of the estate; that son sold the entire operation to Hugh Hamer for $7,000 made in payments. A Hell of a deal for the time.

Hamer wasted no time in setting to work getting the distillery back up and running and before long corn whiskey, apple brandy, and peach brandy was making its way into the local community as well as onto flat boats alongside meal from the grist and pork produced from the 350-400 hogs that were run annually on the property.

Spring Mill has made much in press releases recently about “Old Hamer” whiskey, not to dispute that there may have been such an article aptly named but if there were it probably wasn’t marketed as such until much later in history and would have been only a few months old at best by the time it reached New Orleans via flat boat after the fall distillation season. My searches have turned up no traces of this “Old Hamer” whiskey until the revival of Spring Mill via the conservation corps and subsequent press releases in the 1930’s.

Hamer by all accounts was a hell of a fellow who would help out the men, women, and children of his village anyway he could and subsequently made a small fortune monetarily from his enterprises and a large fortune in friends and family from his good character, but like all mortal men, including Whiskey Barons, the lord came calling for him on March 10, 1872. By then the village had already started it’s decline as the rail road line had bypassed it for nearby Mitchell Indiana several years prior.

Thereafter Johnathan Turley took possession of the property and continued in the business of milling and distilling with his partner Solomon Scott. Solomon himself had deep ties to Distilling himself as he owned another distillery between Mitchell and Bedford in partnership with a Wolfe fellow (this distillery was located across the road from the property where Apple Acres orchard currently sits). They renamed the mill property including the distillery as Daisy Mill and installed a turbine to modernize the milling equipment and began milling wheat flour By this time cornmeal was no longer as nearly in want as what it had been in previous decades given the prevalence of steam powered grinding machines which lessened the need for water power greatly, the mill became primarily a resource of the distillery which built a hell of a name on their well-made brandies and whiskies, the last of which recorded was a batch of Apple Brandy distilled on April 18, 1886. This being four years after Turley had closed the mill to the public, making the distillery by far the most productive of the enterprises associated with the property and the last to remain in operation. Unfortunately, the temperance movement was on the rise, commerce had passed the mill and distillery by and Turley’s health was failing (as was his ability to make a profit from his investment). Turley passed away a few months later.

The story of the distillery would not be complete without the mention of yet two other names, those of the distillers who in fact would have been responsible for the astounding quality of the whiskey and brandy made at that time. The first distiller under Hammer in the 1830’s was James Clouse who was followed by William W. Dalton who made the village and distillery his home and responsibility for over 40 years before he found his final resting place in the old Hammer cemetery on the ridge above the scenic valley. That’s a long career and an admirable legacy for a Hoosier Distiller.

The building as it currently stands was pieced together by the the Conservation Corps in the 1930’s on the footprint of the old distillery. At that time they created two schematics of the distillery based on both their survey and the memories of a gentleman who was alive during the time the distillery was in operation in it’s later years in the 1880’s. Both are similar but I don’t think either is quite accurate as they don’t exactly match the Gaugers surveys or tax records that I will share in this article.

Luckily for us several documents and pieces of equipment from the original distillery still exist on site and at the Indiana State Historical Society. The distillery actually still has the original 100 gallon copper boiler, one original copper 100 gallon pot (with no head), an original worm in a 100 gallon mash tub, at least one other original 100 gallon mash tub, an 8 gallon brandy barrel, and the brand that would have been used to burn “Copper Distilled” on the barrel head. From all of these things we can infer quite a bit.

The wash boiler is as surprising to see extant as what the pot is, these were usually torn from their moorings in a bricked up furnace and recycled for use in the production of apple butter. At some point this particular boiler itself had been used for some such purpose as the outlet drain on the pot had been covered over with a piece of copper and riveted in place. The still is of very early construction and is of a fairly unique design mimicking very much what is seen at the Staley Family Distillery in Ohio.

There are several tell-tale features that link the design with Romani/Gypsy design including the fill port shape. The Staley Gypsies were a staple of Indiana, Ohio, and Kentucky history and were often the go to tin and copper workers of their time and it has been theorized by myself and by many others that they were responsible for the building of many early pot stills in the Ohio valley which all share many design similarities. I have read that in the summer as they took to the wagons to travel from their home base/winter camp in Dayton Ohio they would stop outside of many towns on main thorough fairs and set up camp to offer their services in tin and copperwork. These camps were fenced off by the locals and someone from town would guard the encampment, always armed, from horseback, supposedly to dissuade the Gypsies from pursuing the other (perhaps fictional due to racial bias) “trade”, thievery. If the tax papers are any indication then there were at one point three of these 100 gallon copper stills in operation at the distillery.

The brand is interesting as well because it links directly to the production methodology used in the distilling process. By the late 1800’s many of Indianan’s Farm-Distillers had given up the old pot still methodology and switched over to wooden bodied three chamber stills in order to create a more time efficient operation to deal with the thousands of lbs of apples they were processing yearly. While these stills were very well known for producing high quality Rye whiskey they were unfavored by the consumers of apple brandy and corn whiskey in the local area who had grown up with the old “fire copper” pot still products. Subsequently those operating on the old/traditional plan of distilling began in earnest to market their product as a premium style by using either “Fire Copper” or “Copper Distilled” brands on their barrel heads to mark the difference in their products.

The mash tubs are of 100 gallon capacity and the fact that they are still standing is a testament to how well built they truly were.

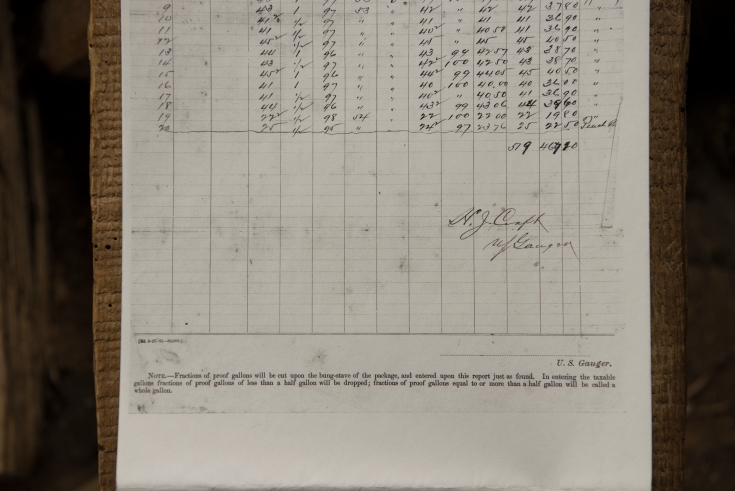

The records the several Gaugers kept that I have access to from around 1880-1883 are fairly detailed and include a lot of very interesting information. Key was understanding of a few base processes used in the distillery as well as capacity. The layout is fairly easy to ascertain; 16 mashtubs of 100 gallon capacity (30 inch base, 34 inch chime rim, and 32 inches of depth) were set upon an elevated wooden decking and used for mashing in whiskey and apple jack brandy. The distillery was equipped with at least one 100 gallon boiler in a stone furnace, and 3 copper pot stills in furnaces. The water was derived from the same flume that feeds the mill and a secondary reservoir built from wood was held inside the building where water was siphoned for needed processes.

Ill delve into the apple jack first. The records indicate that Turley was buying from a number of local farmers, on average he was purchasing roughly 30 bushels of fruit from each farmer and was engaged in producing both Apple Jack from crushed pomace as well as a small amount (3,830 gal) of true brandy from cider. The records also clearly show a large amount of peach brandy from pomace and grape brandy (5,592 gal. of wine) was being produced as well. The indication given in the record is that to every bushel of apple pomace ground that roughly seven gallons of water was added which would make for a very heavy mash bill. The back side of the existing pot still is quite interesting in regards to this as there is an extra port not related to pressure relief, nor to fill, nor to the head, I speculate that there may have in fact been a gear driven rummager or agitator to keep this thick mash moving in the still. This technology was already well known in the distilleries associated with large water mills by as early as 1809 so it wouldn’t be surprising, this too would also result in a very heavily flavored apple spirit wherein tannin and phenolics would all be extracted during distillation as opposed to a distillation relying only a wash (no solids included) charge of the same material.

On the whiskey side the guager only completely fills out the category for Whiskey primarily derived from corn with rye as a secondary grain in his survey of October the 6 1883. Since this is a survey he had to fill out the other columns (Rye in excess, Corn and Rye Equally, Rye Exclusively, and Molasses) as they were gauging the true capacity of the distillery. From this we can infer that what was being made (at least the majority of what was made) sets pretty comftorably in the category we would call either Corn Whiskey or potentially Bourbon Whiskey. Interestingly enough he gives us the expected yield per bushel of both Sweet Mash (3 ½ gallons per bushel) and Sour Mash (2 ½ gallons per bushel) as well as the fermentation period of Sweet Mash (72 hours) and Sour Mash (92 hours) and records in the March 1883 survey that the Daisy Spring distillery uses 6.73 bushels of corn in a 24 hour period for sour mash and 11.97 bushels of corn for a sweet mash as well as that the sweet mash will yield 16.82 gallons of spirit and the sour mash 41.89 gallons of spirit in a 24 hour period. To this we are treated to the viscocity of the beer in distilling where it is reported that the sour mash is a 60 gallon beer (super thin!) and that the sweet mash is a 45 gallon beer (still thin but in line with some of the large Kentucky Distillers).

We also get a good look at the barreling of apple brandy which is recorded generally around 100 proof and mostly in what appear to be 42 gallon barrels (although one is clearly marked as 48 gallons) and being produced in 7-8 gallon lots. Most likely these were “packages” to be delivered to local merchants who would handle direct sales from the barrel directly to the customer. It is unlikely that much of this liquor ever aged for an extended period of time and I would imagine that since the old Hoosier Peach/Apple brandy consumption custom was to add honey to the mix that very little if any of this brandy ever made it past it’s second birthday.

Taxes on a 42 proof gallon barrel of apple brandy in 1883 amount to $37.80. From a second document the distillery is noted at producing between 600-1200 gallons of apple brandy yearly.

The heritage of Distilling at this valley is deep and we’ll documented. Over the years a few volunteers showed interest in the site and it’s interpretation including Andy Evans who married into the Hammer family and researched the facility heavily in the 1980’s before he passed away. He was responsible for collecting many of the documents you see here and preserving many of the artifacts, something he can’t be thanked enough for!

A big thank you to my brother D.J. Henderson for the document photos!

An enjoyable read! Do you know who the couple in the picture is (and what the setting is)? I didn’t see it mentioned in the article.

LikeLike

William Dalton Distiller. I’m not sure if the lady is his wife, mother, or who she may be.

LikeLiked by 1 person

I’m a descendent of William Dalton and I thought that picture looks familiar from family photo stacks. I passed your story along to my brother who is our family historian. I see that a distillery in Indy has somewhat revived the brand and one in West Baden has mined the yeast for an old-style use.

LikeLike

William Dalton is the man. The woman I am not sure.

LikeLike